Tag: pursues

Breaking News

Exclusive interview: Algorand interim CEO Sean Ford says “Our time is now”

Taking place in Dubai, the industry’s newly-adopted “crypto-friendly” hub, we discussed Algorand’s technology and achievements, its plans in the middle east,...

Royal Bahamian Police Force Arrests Sam Bankman-Fried

FTX Founder Sam Bankman-Fried has been arrested. This follows the receipt of official information from the United States. Client and business assets were...

Gbrick Token (GBXT) Is Now Available for Trading on LBank Exchange

INTERNET CITY, DUBAI, Dec. 1, 2022 – LBank Exchange, a global digital asset trading platform, has listed Gbrick Token (GBXT) on December 1, 2022....

Will the future metaverse amplify the good—or the evils—of the real world?

The last month has seen a seismic shift in the fortunes of some of the most powerful tech companies in the world. The chaos...

How Yara is using MLOps features of Amazon SageMaker to scale energy optimization across their ammonia plants

Yara is the world’s leading crop nutrition company and a provider of environmental and agricultural solutions. Yara’s ambition is focused on growing a nature-positive...

Toyota: Construction and Launch of a Large-capacity Sweep Energy Storage System from Reused Electrified Vehicle Batteries Connected to the Electrical Power Grid

|

|

In the future, demand for storage batteries is expected to grow as they become necessary supply-stabilizing tools when expanding renewable energy in the movement toward CO2 emissions reduction, a vital part of achieving carbon neutrality. At the same time, limited supplies of battery materials including cobalt and lithium, mean there is an ongoing need for environmentally conscious initiatives, such as reclaiming used electrified vehicle batteries for effective use as storage batteries. In response, JERA and Toyota began discussions in 2018 to establish battery reuse technologies, which eventually led to this large-capacity, grid-connected Sweep Energy Storage System.

Toyota's new storage system is equipped with a function called sweep, which allows the use of reclaimed vehicle batteries, which have significant differences in performance and capacity, to their full capacity regardless of their level of deterioration. The sweep function, developed by Toyota Central R&D Labs, Inc., is a device that can freely control energy discharge by switching electricity flow on and off (bypassing) through series-connected batteries in microseconds.

Furthermore, the sweep function also enables direct AC output from the batteries, while reusing onboard inverters eliminate the need for a power conditioner (PCS). That contributes to reducing costs and helps avoid power loss when converting from AC to DC by PCS, with the aim of improving effective energy use.

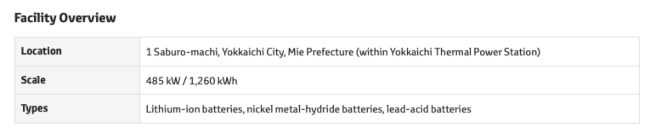

The project plans to operate grid storage batteries for recharge and discharge operations, connected to the Chubu Electric Power Grid Co., Inc. power distribution system from a facility (see below(1)) at JERA's Yokkaichi Thermal Power Station. JERA and Toyota aim to introduce approximately 100,000 kWh of supplied electricity in the mid-2020s, thereby not only reducing the overall cost of the energy storage system, but also contributing to reduction of CO2 emissions.

(1) Selected by Japan's Ministry of the Environment to conduct an "FY2022 Project for Early Social Implementation of a Decarbonized Metal Recycling System."

In addition, JERA is developing a low environmental impact process for recycling lithium-ion batteries for electrified vehicles(2), which Toyota plans to support by leveraging the expertise and knowledge it has accumulated through its battery recycling initiatives to date. By collecting used batteries and reusing resources, both companies hope to accelerate their efforts toward achieving a resource-recycling society.

(2) JERA and Sumitomo Chemical Start a Demonstration Project to Develop a Low Environmental Impact Recycling Process for Electric Vehicle Lithium-ion Batteries (JERA Press Release, April 19, 2022)

JERA will continue to work proactively not only within the energy industry but also with leading companies in Japan and overseas to develop technologies such as battery storage systems and services that contribute to optimal energy utilization toward achieving a decarbonized and resource-recycling society.

Toyota actively promotes electrified vehicle adoption and pursues effective battery use, including electrified vehicle battery reuse, for the development of social infrastructure that will support the widespread adoption of electrified vehicles, expand the use of renewable energy, and promote resource recycling toward achieving carbon neutrality.

Copyright 2022 JCN Newswire. All rights reserved. www.jcnnewswire.comJERA Co., Inc. (JERA) and Toyota Motor Corporation (Toyota) announce the construction and launch of the world's first (as of writing, according to Toyota's investigations) large-capacity Sweep Energy Storage System.

Evolution through large models

This paper pursues the insight that large language models (LLMs) trained to generate code can vastly improve the effectiveness of mutation operators applied to...

MHIENG and MHIEC to Commence Demonstration Testing of Separation, Capture and Effective Use of CO2 from Waste-to-Energy Plant

|

The demonstration testing, a joint undertaking by the private and public sectors, will integrate MHIEC and Yokohama's knowhow in the operation of WtE plants, MHIENG's high-performance carbon capture technology, and Tokyo Gas' expertise in hydrogen and carbon usage. The aim is to separate, capture and effectively recycle the mainly biomass-derived CO2 in the flue gas generated during the incineration of household waste.

Under this project, MHI Group's carbon capture technology will be applied at Yokohama's Tsurumi Waste-to-Energy Plant, which was originally built by MHIEC. MHIENG will design and manufacture the compact CO2 capture system based on its proprietary process technologies, and MHIEC will take charge of the equipment?s installation. The high-purity CO2 separated and captured from the flue gas will be transported to Tokyo Gas?s Yokohama Techno Station, located in Tsurumi-ku, Yokohama, where it will be used for a demonstration test of methanation that synthesizes methane gas through chemical reaction with hydrogen, as well as for research on direct use to industrial gas.

The project will be MHIENG's first application of its CO2 capture technology in a WtE plant. The equipment to be designed and manufactured is a compact CO2 capture system with a capture capacity of 0.3 tonnes per day (tpd), and it is applicable to various industrial facilities. It will further strengthen MHIENG?s product lineup as the company pursues increased applications of its carbon capture technologies to diverse emission sources and scales. For MHI Group, the project is significant in terms of providing a carbon negative solution responding to Japan?s decarbonization needs going forward: implementation of integrated carbon separation and capture from social infrastructure.

MHI Group today is undertaking strategic strengthening of its energy transition business, and the development of a CO2 ecosystem is central to those initiatives. Carbon capture, utilization and storage (CCUS) is garnering attention as an effective means for realizing a carbon neutral society. With the demonstration testing to be performed in Yokohama, MHIENG and MHIEC, key players in MHI?s energy transition program, will contribute to reducing greenhouse gas emissions on a global scale, part of MHI's ongoing commitment to help protect the global environment.

About MHIENG's CO2 capture technologies

MHIENG (originally MHI) has been developing the KM CDR Process and the Advanced KM CDR Process in collaboration with Kansai Electric Power since 1990. Today the Company stands as a global leader in this field. As of February 2022, the KM CDR Process has been adopted at 13 plants worldwide, and three more are currently under construction. For further details, visit the following website. https://www.mhi.com/products/engineering/co2plants.html

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world?s leading industrial groups, spanning energy, logistics & infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.

Copyright 2022 JCN Newswire. All rights reserved. www.jcnnewswire.comMitsubishi Heavy Industries Engineering, Ltd. (MHIENG) and Mitsubishi Heavy Industries Environmental & Chemical Engineering Co., Ltd. (MHIEC) are poised to commence demonstration testing of equipment for separation, capture and effective utilization of CO2 emissions from a local waste-to-energy (WtE) plant.