Tag: demonstration

Breaking News

Warren and Durbin seek answers from Bankman-Fried and FTX’s successor

On November 16, Elizabeth Warren and Richard Durbin sent letters to the former and current CEOs of FTX, Sam Bankman-Fried and John Jay Ray...

IBM partners with Algorithmiq to fine-tune quantum computers for drug discovery

By Dan O'Shea posted 17 Nov 2022 IBM has partnered with Finnish start-up Algorithmiq to embark on a...

News – Quantum Computing Report

Recent news items published within the last 6 months on quantum computing developments are listed below. Click on the hyperlinked item to go to...

Superconductors strengthen signals in scanning-tunnelling microscopy

The sensitivity of a scanning-tunnelling microscope improves by up to a factor of 50 when...

Towards quantum advantage via topological data analysis

Casper Gyurik1, Chris Cade2, and Vedran Dunjko1,31LIACS, Leiden University, Niels Bohrweg 1, 2333 CA Leiden, Netherlands2QuSoft, Centrum Wiskunde & Informatica (CWI), Science Park 123,...

I resigned from my position in Iran and I call on my former colleagues to do the same

Encieh Erfani says that more must be done to support students in Iran who are risking their lives to protest against...

Toyota: Construction and Launch of a Large-capacity Sweep Energy Storage System from Reused Electrified Vehicle Batteries Connected to the Electrical Power Grid

|

|

In the future, demand for storage batteries is expected to grow as they become necessary supply-stabilizing tools when expanding renewable energy in the movement toward CO2 emissions reduction, a vital part of achieving carbon neutrality. At the same time, limited supplies of battery materials including cobalt and lithium, mean there is an ongoing need for environmentally conscious initiatives, such as reclaiming used electrified vehicle batteries for effective use as storage batteries. In response, JERA and Toyota began discussions in 2018 to establish battery reuse technologies, which eventually led to this large-capacity, grid-connected Sweep Energy Storage System.

Toyota's new storage system is equipped with a function called sweep, which allows the use of reclaimed vehicle batteries, which have significant differences in performance and capacity, to their full capacity regardless of their level of deterioration. The sweep function, developed by Toyota Central R&D Labs, Inc., is a device that can freely control energy discharge by switching electricity flow on and off (bypassing) through series-connected batteries in microseconds.

Furthermore, the sweep function also enables direct AC output from the batteries, while reusing onboard inverters eliminate the need for a power conditioner (PCS). That contributes to reducing costs and helps avoid power loss when converting from AC to DC by PCS, with the aim of improving effective energy use.

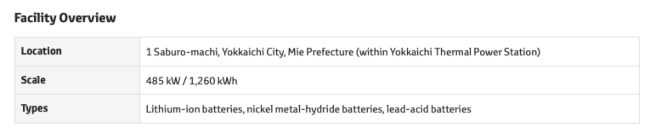

The project plans to operate grid storage batteries for recharge and discharge operations, connected to the Chubu Electric Power Grid Co., Inc. power distribution system from a facility (see below(1)) at JERA's Yokkaichi Thermal Power Station. JERA and Toyota aim to introduce approximately 100,000 kWh of supplied electricity in the mid-2020s, thereby not only reducing the overall cost of the energy storage system, but also contributing to reduction of CO2 emissions.

(1) Selected by Japan's Ministry of the Environment to conduct an "FY2022 Project for Early Social Implementation of a Decarbonized Metal Recycling System."

In addition, JERA is developing a low environmental impact process for recycling lithium-ion batteries for electrified vehicles(2), which Toyota plans to support by leveraging the expertise and knowledge it has accumulated through its battery recycling initiatives to date. By collecting used batteries and reusing resources, both companies hope to accelerate their efforts toward achieving a resource-recycling society.

(2) JERA and Sumitomo Chemical Start a Demonstration Project to Develop a Low Environmental Impact Recycling Process for Electric Vehicle Lithium-ion Batteries (JERA Press Release, April 19, 2022)

JERA will continue to work proactively not only within the energy industry but also with leading companies in Japan and overseas to develop technologies such as battery storage systems and services that contribute to optimal energy utilization toward achieving a decarbonized and resource-recycling society.

Toyota actively promotes electrified vehicle adoption and pursues effective battery use, including electrified vehicle battery reuse, for the development of social infrastructure that will support the widespread adoption of electrified vehicles, expand the use of renewable energy, and promote resource recycling toward achieving carbon neutrality.

Copyright 2022 JCN Newswire. All rights reserved. www.jcnnewswire.comJERA Co., Inc. (JERA) and Toyota Motor Corporation (Toyota) announce the construction and launch of the world's first (as of writing, according to Toyota's investigations) large-capacity Sweep Energy Storage System.

Augmented Reality in Hospitality Industry in 2023

The hospitality industry is changing in a variety of ways. New technologies...

DPC EEU Tour 2 Playoffs: Outsiders Disqualified, Mind Games to finals, and more

The Virtus.pro (Outsiders) roster was disqualified before their match against BetBoom Team in the upper bracket semifinals. This means that Mind Games will receive a retroactive forfeit win for their match earlier today and all future Outsiders would have played are forfeit as well.

ENEOS, Toyota, and Woven Planet Collaborate to Facilitate CO2-free Hydrogen Production and Usage for Woven City and Beyond

|

|

|

As described in the Basic Agreement signed in 2021, ENEOS and Toyota have decided to commence construction and operation of a hydrogen refueling station in close proximity to Woven City to produce and supply CO2-free hydrogen to Woven City and Fuel Cell Electric Vehicles (FCEVs) (Item 1 and 2 set forth below). Together, they will also research and design an efficient hydrogen supply and demand management system (Item 3 described below). The ENEOS hydrogen refueling station is scheduled to begin operations before the opening of Woven City in 2024-2025.

Items to be considered at the time of the Basic Agreement(1)

1. ENEOS to establish and operate a hydrogen refueling station in close proximity to Woven City

2. ENEOS to produce "green hydrogen," hydrogen derived from renewable energy, by electrolyzers at the aforementioned station and supply it to Woven City to be used at a stationary fuel cell generator that will be installed within Woven City by Toyota

3. Promote the use of hydrogen-powered fuel cell mobility for logistics in and nearby Woven City. Validate a base unit(2) of hydrogen demand for those mobility logistics as well as build a supply and demand management system

4. Conduct joint advanced research on hydrogen supply at the demonstration hub to be established within Woven City

The ENEOS hydrogen refueling station will "produce" the hydrogen that will meet the energy needs of "users," FCEVs in and around Woven City and Woven City as well. This collaboration expedites our progress toward realizing a truly carbon-neutral society and will facilitate and normalize clean energy operations first at Woven City and eventually the world.

Woven City is the project of Toyota aiming to create happiness through mobility of "people," "goods," and "information." It is focused on three pillars. That are: Human-Centered City that makes people happier in their everyday lives, considering the needs of different kinds of people before and during the development of technology; Living Laboratory, the first-of-its-kind test track for mobility where researchers, engineers, and scientists demonstrate innovative ideas and future technologies both virtually and in the real world; and Ever-Evolving City, rooted in Toyota's kaizen (continuous improvement) approach, is focused on new ideas that provide better mobility of information, goods, and people.

(1) Announced on May 10, 2021 "ENEOS and Toyota Come Together to Make Woven City the Most Hydrogen-Based Society"

(2) Hydrogen can be supplied to FCEVs even during power outages by using stored hydrogen to operate a hydrogen refueling system with a stationary fuel cell generator. This allows the external power supply function of FCEVs to be utilized to provide power support where electricity is needed.

(3) The "base unit" is a standard of measurement required to ensure a result that is both practically valuable to users and commercially viable.

About ENEOS Corporation

Under ENEOS Holdings, Inc., the ENEOS Group has developed businesses in the energy and nonferrous metals segments, from upstream to downstream. The Group's envisioned goals for 2040 are: becoming one of the most prominent and internationally-competitive energy and materials company groups in Asia, creating value by transforming our current business structure, and contributing to the development of a low-carbon, recycling-oriented society with the pursuit of carbon-neutral status in its own CO2 emissions. ENEOS Corporation, one of the principal operating companies in the Group, is contributing to achievement of the Group's envisioned goals through a broad range of energy businesses.

https://www.hd.eneos.co.jp/english/

https://www.eneos.co.jp/english/

About Toyota Motor Corporation

Toyota Motor Corporation (Toyota) (NYSE: TM) is the global mobility company that introduced the Prius hybrid-electric car in 1997 and the first mass-produced fuel cell sedan, Mirai, in 2014. Headquartered in Toyota City, Japan, Toyota has been making cars since 1937. Today, Toyota proudly employs 370,000 employees in communities around the world. Together, they build around 10 million vehicles per year in 28 countries and regions, from mainstream cars and premium vehicles to mini-vehicles and commercial trucks, and sell them in more than 170 countries and regions under the brands Toyota, Lexus, Daihatsu and Hino.

For more information, please visit https://global.toyota/en

About Woven Planet

Woven Planet is building the safest mobility in the world. A subsidiary of Toyota, Woven Planet innovates and invests in new technologies, software, and business models that transform how we live, work and move. With a focus on automated driving, smart cities, robotics and more, Woven Planet builds on Toyota's legacy of trust to deliver secure, connected, reliable, and sustainable mobility solutions for all.

Learn more at woven-planet.global.

Copyright 2022 JCN Newswire. All rights reserved. www.jcnnewswire.comENEOS Corporation (ENEOS) and Toyota Motor Corporation (Toyota) have signed a joint agreement to explore CO2-free hydrogen production and usage at Woven City, the prototype city of the future that Toyota has started to develop in Susono City, Shizuoka Prefecture, Japan.

MHIET and Calik Enerji to Construct a Demo Plant for Triple Hybrid Stand-alone Power System “EBLOX” in Turkey

|

The plant was built based on the collaboration that was signed in 2019 between MHIET and Calik Enerji Sanayi ve Ticaret A.S. with the goal of developing advanced structure for tailored based demand for Malatya Project and new expanding sales of EBLOX in Africa and neighboring countries of Turkey.(3) Renewable energy can be highly unstable due to changes in the environment and other factors, making it unreliable to power microgrids or minigrids. MHIET developed EBLOX as a solution to this problem, and Calik Enerji showed strong interest in the technology, offered assistance to develop EBLOX and to spread tailored solutions to Turkey, its neighboring countries and Africa etc.

The plant demonstrates how EBLOX can supply power to isolated microgrids, reduce fuel costs, and contribute to decarbonization using renewable energy, and consists of a 120kW solar power system, 150kW/167kWh storage battery, two 34kW gensets, a dummy load device of 300kW, and the control system "COORDY."

Many regions around the world located outside of the grid power network require simple and stand-alone microgrids. At the same time, stand-alone distributed power is increasingly being recognized as a power source in case of natural disasters such as earthquakes, storms, and floods. These factors, along with the worldwide trend toward decarbonization, make renewable energy critical in these areas.

With Calik Enerji's remarkable experience in the targeted regions and MHIET's expertise, both parties aim to promote EBLOX as a strategic solution for carbon neutrality.

(1) For more information about Calik Enerji, please refer to the following URL.

https://www.calikenerji.com

(2) The name EBLOX refers to the combination of blocks of multiple energies that build our society.

https://www.youtube.com/watch?v=qwyN6SOD0PQ

(3) Please refer to the following press release for details on the collaboration between MHIET and Calik Enerji for the promotion of EBLOX.

https://www.mhi.com/group/mhiet/news/20190829.html

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world's leading industrial groups, spanning energy, logistics & infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.

Copyright 2022 JCN Newswire. All rights reserved. www.jcnnewswire.comMitsubishi Heavy Industries Engine & Turbocharger, Ltd. (MHIET) of the Mitsubishi Heavy Industries, Ltd. (MHI) and Calik Enerji Sanayi ve Ticaret A.S. in the group of a comprehensive energy infrastructure affiliate of Calik Holding(1) have constructed a demo plant of their stand-alone Triple Hybrid Power Generation System "EBLOX"(2) in the Republic of Turkey.

MHIENG and MHIEC to Commence Demonstration Testing of Separation, Capture and Effective Use of CO2 from Waste-to-Energy Plant

|

The demonstration testing, a joint undertaking by the private and public sectors, will integrate MHIEC and Yokohama's knowhow in the operation of WtE plants, MHIENG's high-performance carbon capture technology, and Tokyo Gas' expertise in hydrogen and carbon usage. The aim is to separate, capture and effectively recycle the mainly biomass-derived CO2 in the flue gas generated during the incineration of household waste.

Under this project, MHI Group's carbon capture technology will be applied at Yokohama's Tsurumi Waste-to-Energy Plant, which was originally built by MHIEC. MHIENG will design and manufacture the compact CO2 capture system based on its proprietary process technologies, and MHIEC will take charge of the equipment?s installation. The high-purity CO2 separated and captured from the flue gas will be transported to Tokyo Gas?s Yokohama Techno Station, located in Tsurumi-ku, Yokohama, where it will be used for a demonstration test of methanation that synthesizes methane gas through chemical reaction with hydrogen, as well as for research on direct use to industrial gas.

The project will be MHIENG's first application of its CO2 capture technology in a WtE plant. The equipment to be designed and manufactured is a compact CO2 capture system with a capture capacity of 0.3 tonnes per day (tpd), and it is applicable to various industrial facilities. It will further strengthen MHIENG?s product lineup as the company pursues increased applications of its carbon capture technologies to diverse emission sources and scales. For MHI Group, the project is significant in terms of providing a carbon negative solution responding to Japan?s decarbonization needs going forward: implementation of integrated carbon separation and capture from social infrastructure.

MHI Group today is undertaking strategic strengthening of its energy transition business, and the development of a CO2 ecosystem is central to those initiatives. Carbon capture, utilization and storage (CCUS) is garnering attention as an effective means for realizing a carbon neutral society. With the demonstration testing to be performed in Yokohama, MHIENG and MHIEC, key players in MHI?s energy transition program, will contribute to reducing greenhouse gas emissions on a global scale, part of MHI's ongoing commitment to help protect the global environment.

About MHIENG's CO2 capture technologies

MHIENG (originally MHI) has been developing the KM CDR Process and the Advanced KM CDR Process in collaboration with Kansai Electric Power since 1990. Today the Company stands as a global leader in this field. As of February 2022, the KM CDR Process has been adopted at 13 plants worldwide, and three more are currently under construction. For further details, visit the following website. https://www.mhi.com/products/engineering/co2plants.html

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world?s leading industrial groups, spanning energy, logistics & infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.

Copyright 2022 JCN Newswire. All rights reserved. www.jcnnewswire.comMitsubishi Heavy Industries Engineering, Ltd. (MHIENG) and Mitsubishi Heavy Industries Environmental & Chemical Engineering Co., Ltd. (MHIEC) are poised to commence demonstration testing of equipment for separation, capture and effective utilization of CO2 emissions from a local waste-to-energy (WtE) plant.